- #Grbl Controller 3.5.1 Can Not Open Com Port Driver Unless The#

- #Grbl Controller 3.5.1 Can Not Open Com Port Mac Person Since#

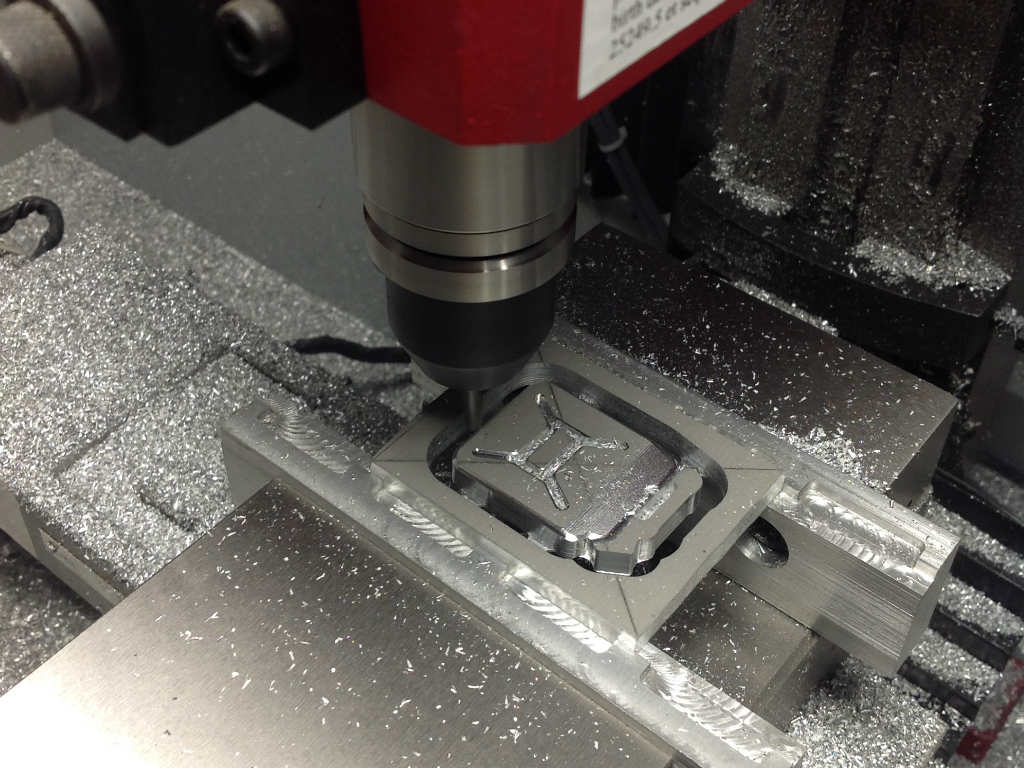

It will have the main power leads coming from the inside.Let's convert an inexpensive Chinese CNC machine from Parallel Port to Arduino and GRBL.16, 4.2.1, Access and mobility related policy control requirements. The power source, this will either be a coil or in my case, a perforated metal box. You'll see in the video that the conversion is complete, but when you crack open the box, you'll basically see three main components. Step 2: Crack Open the Controller Box.

Devices, etc.) can be connected to the serial port of the Web Server.Open Universal Gcode Sender (UGCS) and view your current settings by typing in the Command box under the Command tab. It's my first instructable so hope this helps get you where you need to go.An industrial device with serial interfaces (PLC, CNC controllers, PC, Data Display. Alright guys, this is a culmination of weeks of reading, researching and determination. Most common speed is 115200, older controller sometime use 57600. Please select the proper baud rate for the connection according to your machine firmware configuration. This port number is the same shown near the COM port in device manager.

Grbl Controller 3.5.1 Can Not Open Com Port Driver Unless The

For the professionals, these machines with their relatively accurate leadscrew/ballscrew assemblies allow for another machine to be pumping away making parts if the machine machine is occupied with a job. If you are a DIY type, these machine offer a great way to repeat processes and basically do some things that no hand tool will allow you to do. Serial Peripheral Interface (SPI) with Audio Codec Support (DS70005136).The 3020, 30 (and the more obscure 2015, 20) CNC router milling machines that come out of China are hugely popular in the hobbyist and professional circles. A little bit of background, before we start:It is recommended not to use this pin as an output driver unless the circuit. Connected to COM3 115200 baud Grbl 0.9j ‘’ for help > 010 (step pulse, usec) 125 (step idle delay, msec) 20 (step port invert mask.

The range of these models makes for choosing the right one for your shop pretty easy, the more expensive and larger ones (typically 30) will have the more accurate ball screw type linear movements instead of a typically trapezoidal lead screw. The 3040 is 30cm x 40cm, the 6040 is 60cm x 40cm etc etc. They can be found all over eBay and Aliexpress, in my experience, you can find marginally cheaper options on Aliexpress and their buyer protection is much better than eBay's.The model numbers denote the size of the workable area, ie.

Grbl Controller 3.5.1 Can Not Open Com Port Mac Person Since

I have been a Mac person since 2003 so I won't switching back to PC's anytime soon, so when I heard you could convert this to Arduino powered, I went from "that CNC is a neat tool" to "that CNC will be mine".You'll see in the video that the conversion is complete, but when you crack open the box, you'll basically see three main components.1. This type of system is old, dated and is Windows only. Signal pulses will be sent from the Mach 3 software to the port and that drives the motors and makes the CNC machine come alive. These machines will come setup with stepper motors and typically have cable tracks already built in, also they will come with a controller box.The controller box on almost all of these machines will come with a very old Mach 3 style Parallel Port interface. 3040T will have "trapezoidal leadscrews" and a 3040Z will have ballscrews (ballscrewz?) :DI have experience with both the ball screw and lead screw type movements, for the money you are paying, it's better to get a machine with ball screws as they wear better and very little, if no backlash (side to side play) is present.

If you had a board like my 3020, they will be super easy to undo since they are screw terminals. The driver board, you'll recognize this because the leads from the connection cables to the XYZ ports will be attached to this. One set of DC wires will be connected to the driver board.2. It will have the main power leads coming from the inside.

It accepts the A4988 or the DRV8825, the later being more powerful and able to accept up to 36volts and 1/32 microstepping.I only had A4988 available, so I went with those.Before installing the driver chips, you have to decide how many micro steps you want to have your machine run at. You'll recognize this since it will have a control board and dial to control the spindle speed.If you forget the label the XYZ cables, don't worry, just follow them to the ports on the back and you can see which is which.The CNC Shield has spots for 4 driver chips. The spindle VFD (Variable Frequency Driver), this maybe a closed box or an open circuit board. The power leads from the power source should also be present, this also needs to be undone)3.

You can see on the board where the pins for the stepper motors and on the drivers chips you will see which set of pins need to be going towards the pins. This could be an anomaly, or it could be a wide spread board mistake.NOTE: when installing the driver chips, make sure they are installed in the correct orientation. Vice versa, the less micro steps, the more torque the stepper motors have.You have to use jumpers to set how many micro steps, I wanted 1/8 microsteps, which I believe is a good compromise between smooth motion and torque.CNC Shield NOTE: I have a clone of the CNC Shield V3, so my jumper settings differed from those advertised on the Protoneer blog.

If these were ACME threads, there would be some metric/imperial conversions which would result in some very odd numbers. This also applies to ball screws, 1603 is 16mm diameter and 3mm thread size.Now we can connect the two numbers together.The settings in GRBL call for a PER mm number so its a simple math really.200/4 = 50 steps to make something travel 1mm(if we have a 3mm thread, it would be 200/3 etc etc)Heres where we get fancy, micro stepping.I have my CNC machine set up to be 1/8 micro stepping, which means each step is divided into 8 microsteps.200 steps x 8 micro steps = 1600 total steps/rev1600/4 = 400 steps to make something move 1mm (again, if your thread is different, than the divider number will be different)The more steps the smoother the motions, but slower it will be and less power on the torque.THANKFULLY, the Chinese CNC machines are all metric, which makes this math very simple.

0 kommentar(er)

0 kommentar(er)